Understanding Hepa Filtration Systems For Mold Removal Containment is essential. —

Understanding HEPA Filtration Systems for Mold Removal Containment

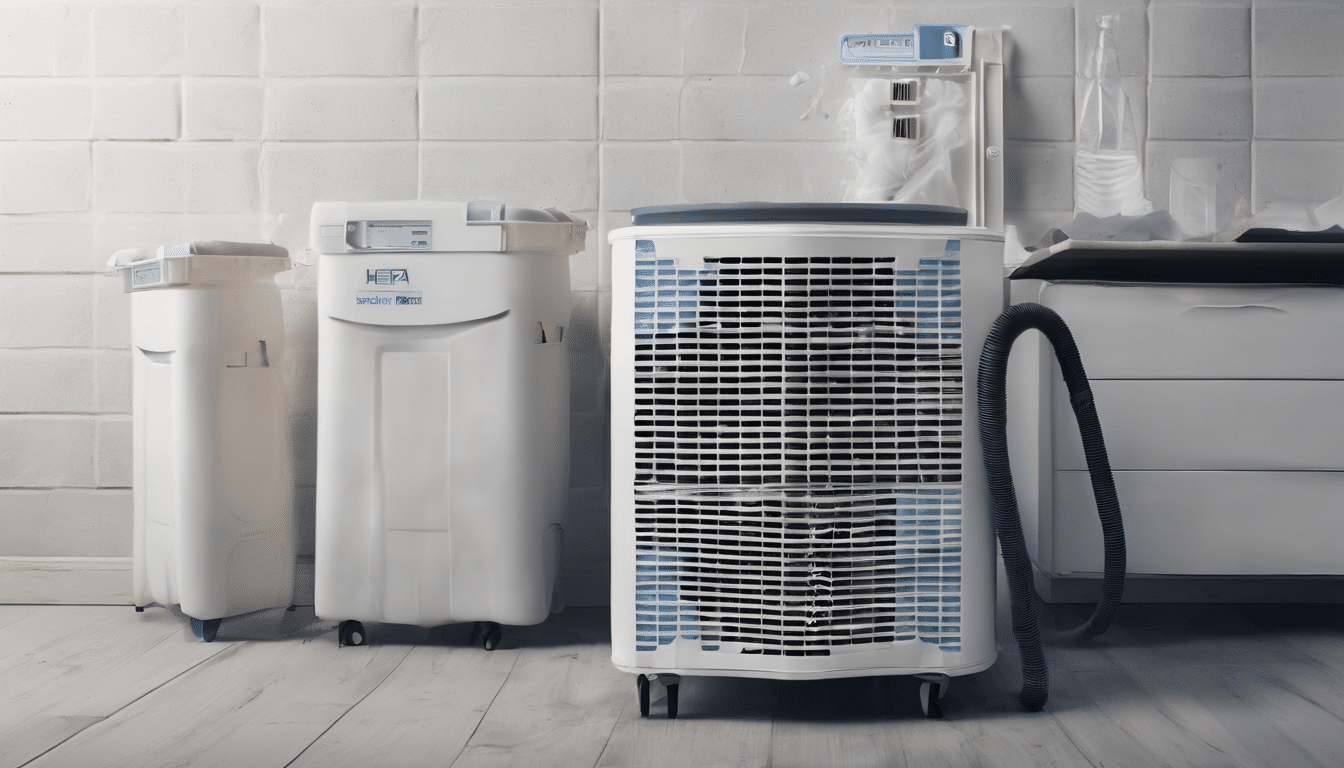

HEPA (High Efficiency Particulate Air) filtration systems are a critical component in mold removal containment strategies. These systems not only ensure that the air within the remediation area is free of harmful particles but also maintain negative pressure, which prevents contaminated air from escaping into other areas of the building.

Hepa Filtration Systems For Mold Removal Containment – Why Is Negative Pressure Important?

Negative pressure is essential in mold removal containment as it creates a barrier that stops airborne spores and contaminants from spreading to unaffected areas. This controlled environment allows for safe and efficient mold remediation, protecting both the building occupants and the professionals involved.

How to Set Up a Negative Pressure Room Properly

To set up a negative pressure room effectively, several factors must be considered. First, the room should have at least one air intake vent on the ceiling and multiple exhaust vents near the floor. The differential pressure between the inside and outside of the room is crucial; typically, this range is 0.1 to 0.2 inches of water column (in H2O). This setup ensures that clean air enters the room while contaminated air is expelled.

Controlling the Pressure Differential

The pressure differential can be controlled using various devices, such as static pressure switches or digital monitors. These tools help maintain consistent airflow and prevent breaches in containment.

HEPA Filter Sizes and Filtration Rates for Mold Removal Containment

Choosing the right HEPA filter size and filtration rate is critical for effective mold removal. Filters should be rated to capture particles as small as 0.3 microns, which is typically the size of airborne spores. For larger rooms or those with high levels of contamination, multiple filters may be required.

Filter sizes can range from 12 inches (30 cm) to 40 inches (100 cm), and filtration rates should match the room’s air volume. Typically, a 150-cubic-foot-per-minute (CFM) filter is sufficient for small rooms, while larger areas may require up to 600 CFM.

Negative Pressure Monitoring and Maintenance

Continuous monitoring of negative pressure levels is essential. This can be achieved through the use of pressure gauges or digital sensors that provide real-time data. Regular maintenance of filters, ducts, and fans ensures optimal performance and longevity.

Common Maintenance Tasks

Regularly inspecting and cleaning filters, replacing them when necessary, and checking for any leaks in the containment system are crucial steps to maintain negative pressure. This proactive approach prevents unexpected breaches that could compromise the remediation process.

HEPA Filtration Systems in Mold Remediation Training

Training professionals on the proper use and maintenance of HEPA filtration systems is vital. This includes understanding how to set up negative pressure rooms, interpret monitoring data, and perform routine maintenance tasks. Regular training sessions can help ensure that all team members are well-prepared for mold remediation projects. This relates directly to Hepa Filtration Systems For Mold Removal Containment.

Tips for Using HEPA Filtration Systems Effectively

To maximize the effectiveness of HEPA filtration systems, follow these tips:

- Ensure proper installation and sealing of filters to prevent leaks.

- Regularly inspect and clean filters according to manufacturer guidelines.

- Use multiple filters if necessary for larger rooms or high contamination levels.

- Monitor pressure differentials continuously during the remediation process.

- Implement a comprehensive containment plan, including proper sealing of doors and windows.

FAQ About HEPA Filtration Systems

Q1: How often should I replace my HEPA filters?

A1: Filters should be replaced every 6 to 12 months or as soon as they become clogged, based on the manufacturer’s recommendations.

Q2: Can a single HEPA filter handle multiple rooms?

A2: A single HEPA filter is typically designed for a specific room size. Using it in multiple rooms can dilute its effectiveness and compromise containment.

Q3: What are the signs that my HEPA filtration system needs maintenance?

A3: Signs include decreased air flow, increased noise from filters, or visible dirt accumulation on the filter surface. Regular inspection is key to identifying these issues early.

Conclusion

HEPA filtration systems play a crucial role in mold removal containment by maintaining negative pressure and filtering out harmful particles. Proper setup, regular maintenance, and training are essential for successful remediation projects. Understanding the importance of these systems can help ensure that indoor environments remain safe and healthy.

—

HEPA Filtration Systems for Mold Removal Containment – Guide to Setting Up Negative Pressure Rooms, Choosing Filters, and Maintenance.

—

Table of Contents

- Understanding HEPA Filtration Systems for Mold Removal Containment

- Why Is Negative Pressure Important?

- How to Set Up a Negative Pressure Room Properly

- HEPA Filter Sizes and Filtration Rates for Mold Removal Containment

- Negative Pressure Monitoring and Maintenance

- HEPA Filtration Systems in Mold Remediation Training

- Tips for Using HEPA Filtration Systems Effectively

- FAQ About HEPA Filtration Systems

—

Understanding HEPA Filtration Systems for Mold Removal Containment

HEPA filtration systems are essential in mold removal containment strategies, ensuring that air is free of harmful particles and maintaining negative pressure to prevent the spread of contaminants. These systems not only filter airborne spores but also create a barrier that keeps contaminated air contained.

Why Is Negative Pressure Important?

Negative pressure is crucial in mold removal containment as it creates a controlled environment where harmful particles are captured and prevented from spreading to unaffected areas. This helps protect both the building occupants and professionals involved, ensuring safe and effective remediation.

How to Set Up a Negative Pressure Room Properly

To set up a negative pressure room effectively, consider having one air intake vent on the ceiling and multiple exhaust vents near the floor. The differential pressure should be between 0.1 and 0.2 inches of water column (in H2O) to ensure clean air enters while contaminated air is expelled.

HEPA Filter Sizes and Filtration Rates for Mold Removal Containment

Selecting the right HEPA filter size and filtration rate is crucial. Filters should capture particles as small as 0.3 microns, while larger rooms or high contamination levels may require multiple filters. Typical sizes range from 12 inches to 40 inches with CFM ratings that match room air volume.

Negative Pressure Monitoring and Maintenance

Continuous monitoring of negative pressure is essential using pressure gauges or digital sensors. Regular maintenance, including inspecting and cleaning filters, ensures optimal performance and longevity, preventing unexpected breaches. When considering Hepa Filtration Systems For Mold Removal Containment, this becomes clear.

HEPA Filtration Systems in Mold Remediation Training

Proper training on HEPA filtration systems is crucial for professionals. This includes setting up negative pressure rooms, interpreting monitoring data, and performing routine maintenance tasks to ensure successful mold remediation projects.

Tips for Using HEPA Filtration Systems Effectively

- Ensure proper installation and sealing of filters to prevent leaks.

- Regularly inspect and clean filters according to manufacturer guidelines.

- Use multiple filters if necessary for larger rooms or high contamination levels.

- Monitor pressure differentials continuously during remediation.

- Implement a comprehensive containment plan, including sealing doors and windows.

FAQ About HEPA Filtration Systems

Q1: How often should I replace my HEPA filters?

A1: Filters should be replaced every 6 to 12 months or as soon as they become clogged, based on manufacturer’s recommendations.

Q2: Can a single HEPA filter handle multiple rooms?

A2: A single HEPA filter is typically designed for a specific room size. Using it in multiple rooms can dilute its effectiveness and compromise containment.

Q3: What are the signs that my HEPA filtration system needs maintenance?

A3: Signs include decreased air flow, increased noise from filters, or visible dirt accumulation on the filter surface. Regular inspection is key to identifying these issues early.

Conclusion

HEPA filtration systems are critical for mold removal containment in Dubai and UAE buildings. Proper setup, regular maintenance, and training are essential for successful remediation projects. Understanding the importance of these systems can help ensure indoor environments remain safe and healthy.

—