Introduction

Understanding How HEPA Filters Work During Mold Remediation Projects is essential. In the context of mold remediation, the use of HEPA (High-Efficiency Particulate Air) filters is a critical component in maintaining indoor air quality and preventing cross-contamination. These filters are designed to capture particles as small as 0.3 microns with an efficiency rate of at least 99.97%. This article aims to provide a comprehensive understanding of how HEPA filters function during mold remediation projects, highlighting their benefits and limitations.

How Hepa Filters Work During Mold Remediation Projects: How HEPA Filters Work

HEPA filters are designed to capture fine particulate matter, including mold spores and other allergens. They use a multi-stage filtration process involving:

- Fiber-based filtering: The filter media consists of layers of fibers that trap particles as they pass through.

- Baffling effect: Air is forced to change direction, causing larger particles to collide with the filter fibers and be captured.

- Sintering: Microscopic fibers are fused together, creating a more effective barrier for smaller particles.

When air passes through a HEPA filter, it first encounters the outer layers, where larger particles are trapped. As air continues to flow, it is forced to change direction and pass through the inner layers, capturing even finer particles including mold spores. The result is clean air that can be safely circulated back into the environment.

Filter Efficiency

HEPA filters are tested and certified by independent organizations such as NIOSH (National Institute for Occupational Safety and Health) to ensure they meet specific efficiency standards. A filter must capture 99.97% of particles at least 0.3 microns in size. For mold remediation, this means that even tiny spores are effectively removed from the air. This relates directly to How Hepa Filters Work During Mold Remediation Projects.

How Hepa Filters Work During Mold Remediation Projects – Benefits of Using HEPA Filters

The use of HEPA filters during mold remediation projects offers several key benefits:

- Prevention of Cross-Contamination: By filtering out harmful spores, HEPA filters prevent the spread of mold to unaffected areas.

- Maintenance of Air Quality: Clean air is essential for both the health of occupants and the effectiveness of remediation efforts. HEPA filters ensure that breathable air remains available throughout the process.

- Enhanced Safety for Occupants: HEPA filters can protect those with allergies, asthma, or other respiratory conditions from exposure to harmful spores.

Reducing Risk of Recontamination

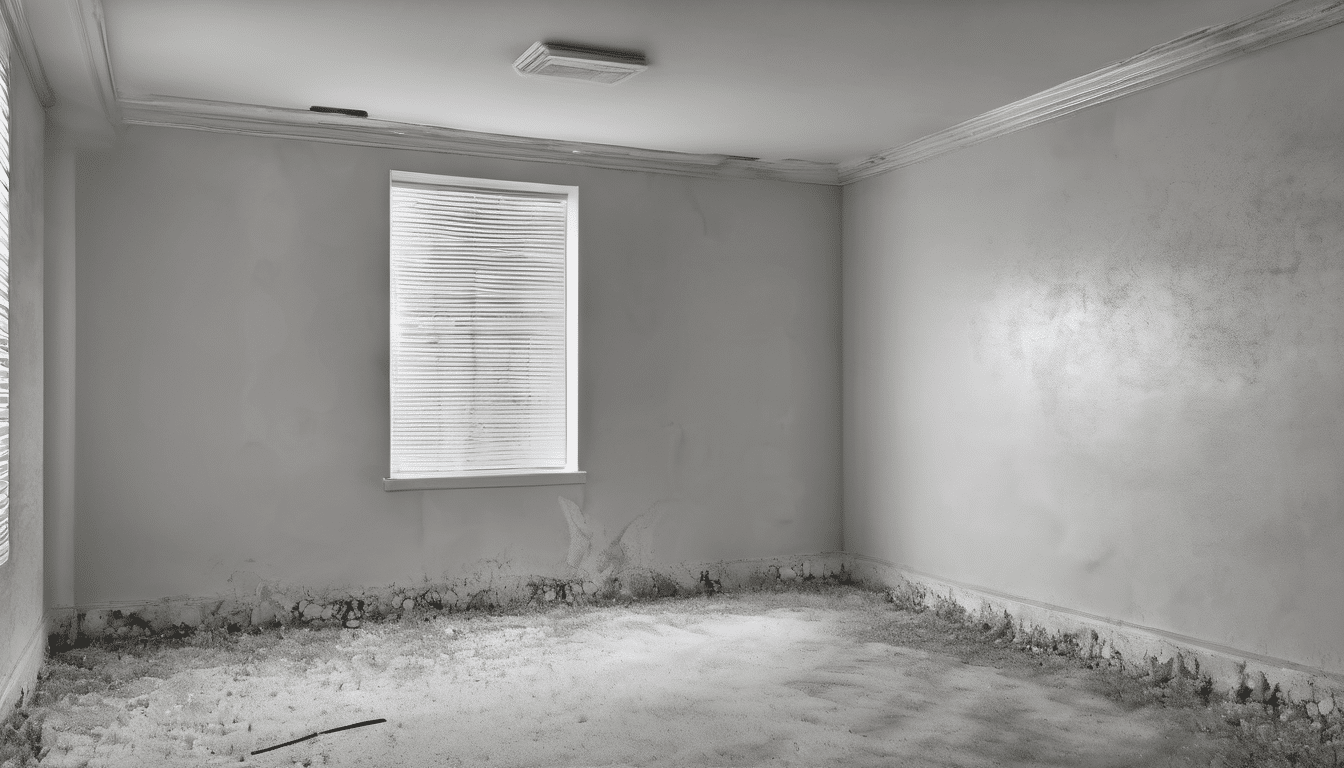

Mold remediation is not just about removing visible mold but also addressing the underlying issues that led to its growth. HEPA filters help by ensuring that any remaining spores are captured and do not recontaminate the affected area. When considering How Hepa Filters Work During Mold Remediation Projects, this becomes clear.

How Hepa Filters Work During Mold Remediation Projects – Limitations and Considerations

While HEPA filters are highly effective, there are limitations and considerations to keep in mind:

- Cost: Installing and maintaining HEPA filtration systems can be expensive, especially for large-scale projects.

- Energy Consumption: The operation of HEPA filters requires significant energy, which may impact the overall cost-effectiveness of the remediation process.

- Filter Maintenance: Regular maintenance and replacement of filters are necessary to maintain their effectiveness. Failure to do so can compromise air quality.

<h2 id="negative-air-pressure”>Negative Air Pressure in Mold Remediation Projects

Negative air pressure is a critical component of mold remediation projects that complements the use of HEPA filters. Negative air pressure creates a controlled environment where contaminated air is not allowed to escape into unaffected areas. The importance of How Hepa Filters Work During Mold Remediation Projects is evident here.

- Containment: By maintaining negative air pressure, contaminants are contained within the affected area and do not spread to other parts of the building.

- Airflow Control: Negative air pressure ensures that clean air is drawn in from unaffected areas while contaminated air is forced through HEPA filters before being released back into circulation.

Optimizing Ventilation for Long-Term Mold Prevention

While HEPA filters are crucial during active mold remediation, they should not be relied upon as the sole method of preventing future occurrences. Proper ventilation is essential to maintain long-term indoor air quality and prevent the recurrence of mold growth.

- Air Drying Systems: Employing air drying systems can help reduce moisture levels in affected areas, making it less hospitable for mold spores.

- Ventilation Strategies: Strategic placement of vents and fans can help distribute clean air throughout the building while reducing humidity levels that promote mold growth.

Contamination Control Measures During Mold Removal

In addition to HEPA filters and negative air pressure, several other measures can be taken to control contamination during mold removal: Understanding How Hepa Filters Work During Mold Remediation Projects helps with this aspect.

- Containment Barriers: Installing physical barriers such as plastic sheeting can prevent the spread of airborne spores.

- Personal Protective Equipment (PPE): Wearing appropriate PPE, including respirators and protective clothing, minimizes exposure to harmful particles.

Expert Tips for Effective HEPA Filter Use in Mold Remediation

To ensure the most effective use of HEPA filters during mold remediation projects:

- Proper Installation: Ensure that HEPA filters are installed correctly to maximize their efficiency.

- Regular Maintenance: Replace or clean filters as recommended by manufacturers to maintain optimal performance.

- Complementary Measures: Use negative air pressure and other contamination control measures in conjunction with HEPA filtration for the best results.

FAQ Section

Here are some common questions about using HEPA filters during mold remediation projects:

- Q: Are HEPA filters necessary during mold remediation?

- A: Yes, HEPA filters are essential for preventing cross-contamination and maintaining air quality.

- Q: Can HEPA filters remove all types of mold spores?

- A: While HEPA filters are highly effective at capturing most spores, extremely fine or volatile spores may not be fully removed. Regular testing is recommended to ensure complete remediation.

- Q: How often should HEPA filters be replaced during a project?

- A: Filters should be checked and replaced as needed based on manufacturer recommendations and the severity of contamination. Frequent replacement ensures ongoing effectiveness.

How Hepa Filters Work During Mold Remediation Projects factors into this consideration.

Conclusion

HEPA filters play an indispensable role in mold remediation projects by ensuring that air remains clean, preventing cross-contamination, and enhancing overall safety for occupants. While they offer significant benefits, it is crucial to understand their limitations and use them in conjunction with other control measures such as negative air pressure and proper ventilation strategies. Understanding How Hepa Filters Work During Mold Remediation Projects is key to success in this area.