Understanding Hidden Mold Detection With Thermal Imaging Technology is essential.

Table of Contents

Introduction to Hidden Mold Detection with Thermal Imaging Technology

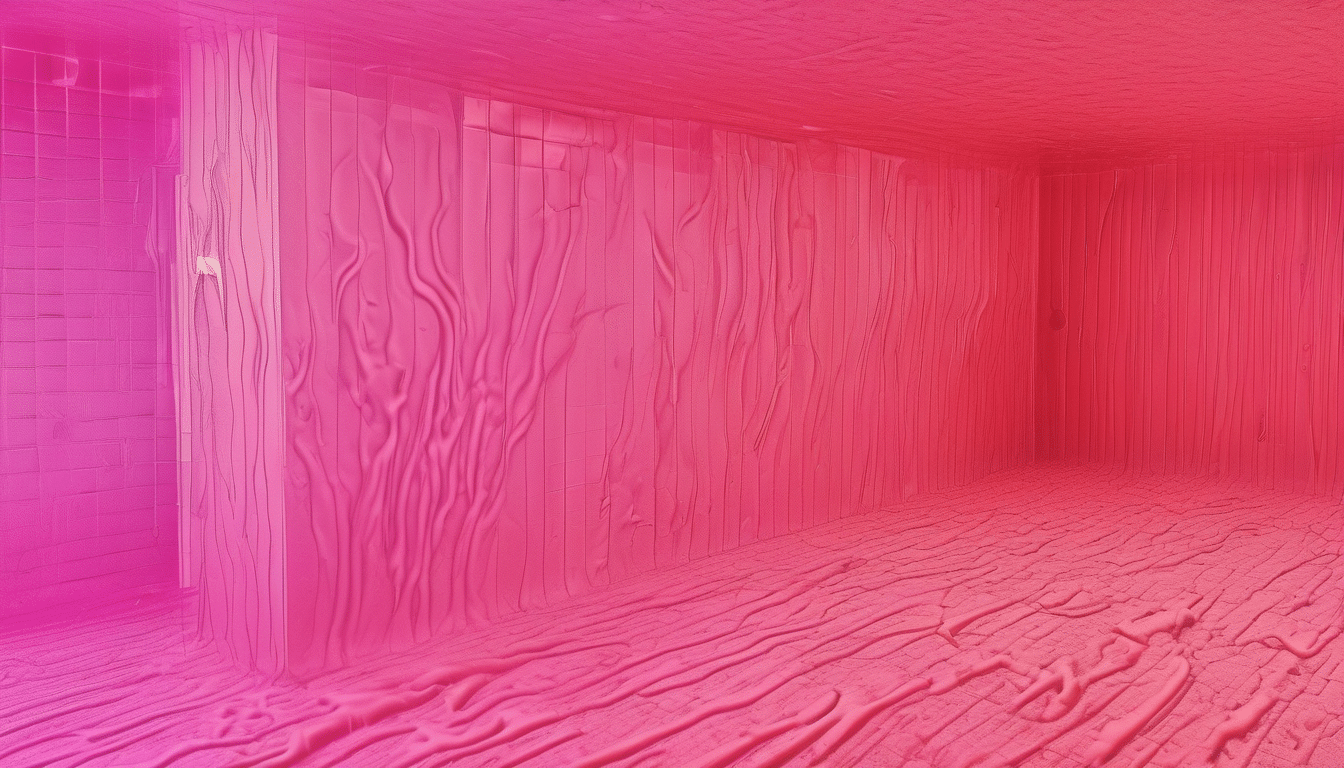

Hidden mold detection is a critical aspect of indoor environmental health, especially in regions like Dubai and the UAE where high humidity and air conditioning create favorable conditions for mold growth. Traditional visual inspections often fail to reveal hidden mold due to its concealed locations or camouflaged appearance. Thermal imaging technology, however, offers a more comprehensive approach by revealing temperature variations that can indicate moisture build-up and potential mold growth.

This article will guide you through the process of using thermal imaging technology for accurate hidden mold detection in your home or office. We’ll explore its benefits, how it works, common mistakes to avoid, and provide practical tips and recommendations for effective use.

What is Thermal Imaging Technology?

Thermal imaging technology uses infrared cameras to capture temperature variations within a space. These cameras detect heat signatures that are invisible to the naked eye, making them invaluable tools in various industries including construction, HVAC, and indoor environmental health.

In the context of mold detection, thermal imaging can identify areas with elevated moisture levels by showing cooler spots where condensation or water intrusion might be occurring. This technology is particularly useful for uncovering hidden mold growth behind walls, under floors, or within HVAC systems that are not easily visible.

Benefits of Using Thermal Imaging for Mold Detection

Thermal imaging provides several advantages over traditional methods when it comes to mold detection:

- Non-Invasive: Unlike destructive sampling techniques, thermal imaging can be performed without damaging the structure or altering the environment.

- Comprehensive Coverage: It allows for a broad area scan, identifying multiple potential sources of moisture and mold growth simultaneously.

- Rapid Assessment: Thermal imaging can quickly pinpoint suspicious areas that may require further investigation, saving time and resources.

- Visual Evidence: The thermal images provide clear visual evidence of moisture hotspots, making it easier to communicate findings to clients or property managers.

How Thermal Imaging Works in Mold Detection

Thermal imaging works by detecting the heat signatures emitted by objects and surfaces. In the case of mold detection, moisture-rich areas will cool down due to evaporation, creating distinct temperature patterns that can be seen on thermal images.

Mold thrives in warm, moist environments, which leads to increased evaporation and lower surface temperatures. This differential cooling is what thermal imaging technology uses to locate hidden mold growth:

- Moisture Detection: Areas with high moisture content will appear cooler on the thermal image compared to drier areas.

- Heat Map Analysis: By analyzing these temperature variations, technicians can map out potential mold hotspots and conduct targeted investigations.

- Verification of Hidden Mold: Once suspected areas are identified, a follow-up with other methods (like surface or air sampling) is necessary to confirm the presence of mold.

Common Mistakes to Avoid with Thermal Imaging for Mold Detection

While thermal imaging technology offers significant advantages, there are common mistakes that can compromise its effectiveness. Here are some key issues to avoid:

- Inadequate Training: Untrained operators may misinterpret the data or overlook important temperature variations.

- Insufficient Data Collection: Gathering insufficient data, such as not taking readings from multiple angles or over different periods, can lead to incomplete results.

- Misusing Technology: Using thermal imaging for mold detection without proper calibration and adherence to standards can yield inaccurate results.

- Ignoring Environmental Factors: Failing to account for external factors like direct sunlight or nearby heat sources that could skew temperature readings.

Selecting the Right Thermal Imaging Device

Choosing the right thermal imaging device is crucial for accurate hidden mold detection. Key considerations include:

- Sensitivity and Resolution: Devices with high sensitivity (low noise) and resolution can capture finer temperature variations, improving accuracy.

- Calibration and Certification: Ensure the device is calibrated regularly and certified for environmental use to maintain reliability.

- Field Capabilities: Look for devices with features like on-screen annotation tools that allow you to mark suspicious areas directly on the image.

- Portability and Durability: Devices should be lightweight, easy to transport, and durable enough for fieldwork in various conditions.

Case Study on Hidden Mold Detection with Thermal Imaging Technology

A recent case study involving a high-rise apartment complex in Dubai highlighted the effectiveness of thermal imaging in detecting hidden mold. The building experienced recurring humidity issues, leading to repeated mold problems despite visual inspections yielding no visible signs.

Using a thermal imaging device, an indoor environmental consultant was able to identify several areas with temperature variations indicative of moisture build-up and potential mold growth behind walls and within HVAC systems. Further investigation using traditional methods confirmed the presence of hidden mold in these locations, leading to targeted remediation efforts that resolved the recurring issues.

Expert Tips for Thermal Imaging Use in Mold Detection

To maximize the effectiveness of thermal imaging technology in mold detection:

- Regular Calibration: Calibrate your device regularly to ensure accurate temperature readings.

- Environmental Control: Conduct scans during periods when conditions are stable, avoiding direct sunlight or extreme temperatures that can affect results.

- Multidisciplinary Approach: Combine thermal imaging with other diagnostic methods (surface and air sampling) for comprehensive assessment.

- Data Documentation: Record detailed data from each scan, including environmental conditions, to facilitate future reference.

- Client Communication: Clearly communicate the findings using visual aids like thermal images to educate clients about hidden mold risks.

Frequently Asked Questions About Hidden Mold Detection with Thermal Imaging Technology

Here are some common questions about using thermal imaging for hidden mold detection:

- Q: Can thermal imaging detect all types of mold?

- No, while it can identify moisture hotspots that may indicate potential mold growth, follow-up with other methods is necessary to confirm the presence and type of mold.

Q: How often should I use thermal imaging for mold detection?

This depends on your specific needs. For high-risk areas or properties with recurring moisture issues, regular scans may be advisable.

Q: Is thermal imaging suitable for all building types?

Thermal imaging can be used in various building types, but its effectiveness may vary based on the construction materials and HVAC systems present.

Conclusion on Thermal Imaging for Hidden Mold Detection

Thermal imaging technology is a powerful tool for hidden mold detection in indoor environments. By providing non-invasive, comprehensive coverage and rapid assessment capabilities, it offers valuable insights into moisture-related issues that can lead to mold growth.

To ensure accurate results, select the right thermal imaging device, avoid common mistakes, and combine its use with other diagnostic methods. With proper training and adherence to best practices, thermal imaging can significantly enhance your ability to detect hidden mold and prevent associated health risks.