EXCERPT: Understanding operational costs of air scrubbers during mold remediation is essential for Dubai professionals. From initial investment to maintenance expenses, managing these costs effectively ensures successful projects. This complete guide reveals 9 key factors for air scrubbers during mold remediation in UAE properties.

Table of Contents

- Introduction to Air Scrubbers During Mold Remediation

- Understanding Operational Costs

- Factors Affecting Operating Costs in Dubai

- Types of Air Scrubbers and Their Costs

- Running Time and Efficiency

- Maintenance Costs and Labor

- Post-Remediation Air Quality Monitoring

- Expert Tips for Managing Operational Costs

- Frequently Asked Questions

- Conclusion on Managing Costs

Introduction to Air Scrubbers During Mold Remediation

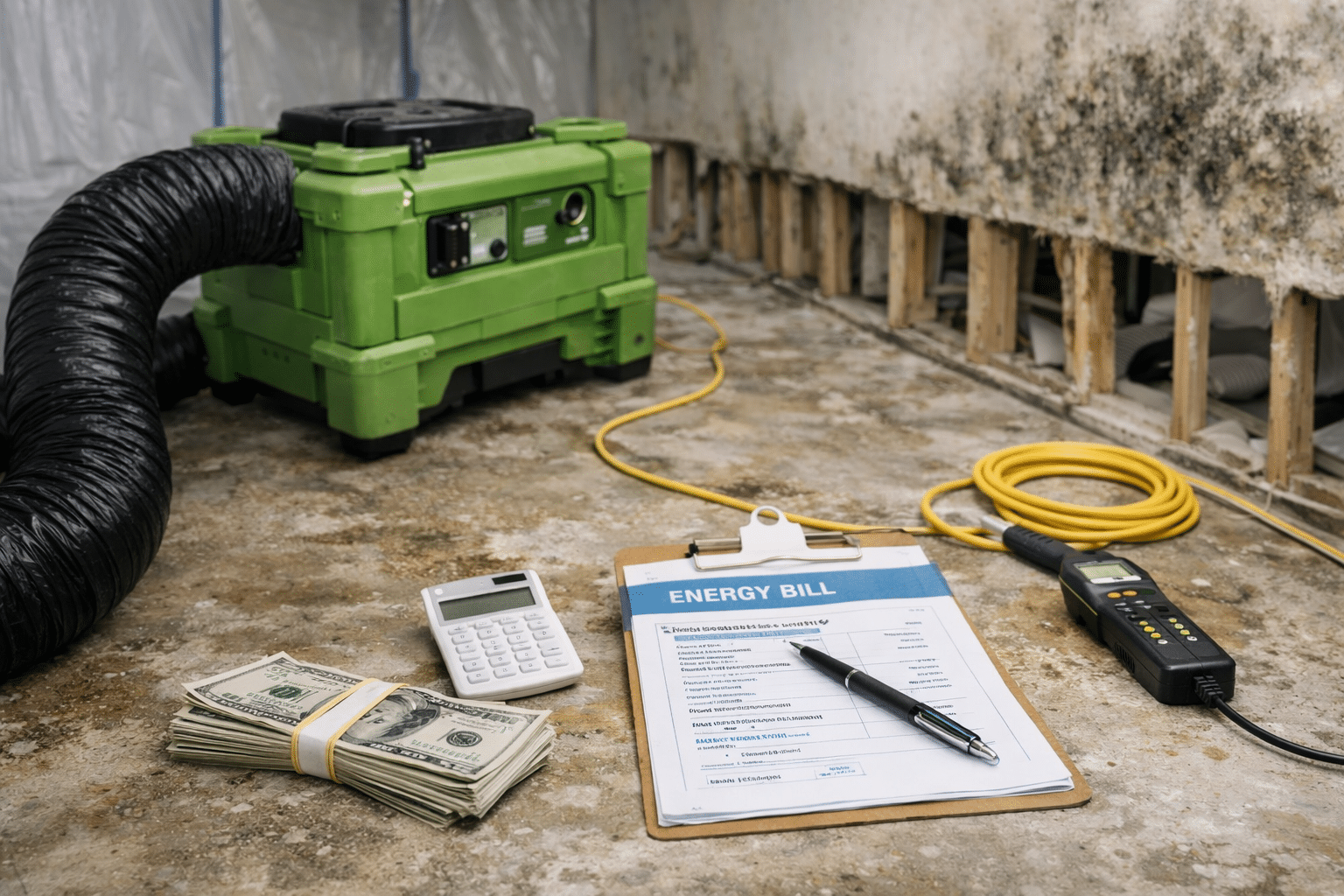

When tackling mold remediation projects in Dubai and the UAE, one significant factor that cannot be overlooked is the operational costs associated with using High-Efficiency Particulate Air (HEPA) air scrubbers during mold remediation. These devices play a critical role in maintaining clean indoor air quality during and after the remediation process. This article provides an in-depth analysis of key factors affecting these costs, helping Dubai professionals manage their budgets effectively.

Understanding Operational Costs

The operational costs of using air scrubbers during mold remediation are multifaceted and can vary significantly depending on several factors. This section explores the primary components that contribute to these expenses in Dubai properties.

Initial Investment

HEPA air scrubbers during mold remediation come in various sizes and capabilities, each with its own price tag. For smaller residential projects in Dubai, portable HEPA units might suffice, costing around AED 5,000 to AED 10,000. Larger commercial or industrial settings may require larger systems that can cost up to AED 30,000 or more.

Operating Costs

Operating costs include electricity and filter replacement. High-quality HEPA filters can range from AED 500 to AED 2,000 per unit, depending on the size and capacity required for the project in Dubai.

Factors Affecting Operating Costs in Dubai

Several factors can influence the operational costs of air scrubbers during mold remediation. Understanding these will help in making informed decisions about budget allocation in UAE projects.

Project Scale

The size and scope of the mold remediation project significantly impact operating costs. Larger Dubai projects with more extensive air filtration needs require higher operating expenses, including increased electricity usage and potentially more frequent filter replacements.

Environmental Conditions

Areas in Dubai with high humidity or where mold growth is prevalent may necessitate longer running times for air scrubbers during mold remediation, leading to higher operational costs. In such environments, the need for additional dehumidification measures can further increase expenses.

Types of Air Scrubbers and Their Costs

Different types of air scrubbers during mold remediation offer varying levels of efficiency and cost-effectiveness. Understanding their differences is crucial in managing operational costs in Dubai.

Portable vs. Centralized Systems

Portable HEPA units are generally more affordable but may require multiple devices for large Dubai spaces, increasing overall operating costs. Centralized systems can be more expensive initially but offer better efficiency and lower long-term costs.

Running Time and Efficiency

The running time of air scrubbers during mold remediation is a critical factor in operational costs. Running them for extended periods can significantly increase energy bills in Dubai. However, optimizing their use based on specific project needs can help reduce these expenses.

Energy-Efficient Designs

Choosing energy-efficient HEPA units with low power consumption can lower electricity bills and overall operational costs without compromising performance. Look for models with high MERV ratings and efficient motor technologies to ensure optimal performance at reduced operating expenses in Dubai properties.

Maintenance Costs and Labor

Regular maintenance is essential to keep air scrubbers during mold remediation functioning optimally, which can add to the operational costs. This includes filter replacements, cleaning, and calibration checks. Skilled labor may also be required for installation and setup in Dubai, further increasing expenses.

Filter Replacement

The frequency of filter replacement depends on project conditions and usage. For instance, in Dubai areas with high dust levels or frequent mold growth, filters might need replacing every 1-2 months, which can add to the overall costs.

Post-Remediation Air Quality Monitoring

Ensuring air quality post-remediation is crucial. Continuous monitoring using air scrubbers during mold remediation helps maintain clean indoor environments in Dubai but also adds to operational costs.

Air Quality Testing Tools

Investing in portable air quality testing tools can provide real-time data, allowing for more informed decision-making and potentially reducing the running time of HEPA units. These devices typically cost AED 2,000 to AED 5,000 in Dubai.

Expert Tips for Managing Operational Costs

Managing operational costs effectively requires strategic planning and attention to detail. Here are some practical tips for air scrubbers during mold remediation:

- Evaluate project needs carefully: Assess the specific requirements of each Dubai mold remediation project to determine the necessary air scrubber size and running time.

- Invest in energy-efficient units: Opt for HEPA units with low power consumption and high MERV ratings to reduce electricity bills in Dubai.

- Regular maintenance schedule: Establish a routine maintenance plan to extend the lifespan of your equipment and minimize replacement costs.

- Use advanced monitoring tools: Employ portable air quality testing devices to optimize running times and ensure compliance with Dubai indoor air quality standards.

Frequently Asked Questions

Q: How often do I need to replace HEPA filters for air scrubbers during mold remediation in Dubai?

A: The frequency depends on project conditions. Typically, every 1-2 months for high-dust Dubai environments.

Q: Can I use standard air scrubbers instead of HEPA units during mold remediation?

A: Standard air scrubbers are less effective and may not meet strict mold remediation standards in Dubai. Always opt for HEPA-rated devices.

Q: Are there any cost-saving alternatives to running air scrubbers during mold remediation continuously?

A: Consider using dehumidifiers in conjunction with HEPA units or scheduling shorter, more frequent operating periods based on real-time monitoring data in Dubai properties.

Conclusion on Managing Costs

Managing the operational costs of using air scrubbers during mold remediation requires a strategic approach. By understanding the key factors that influence these expenses and implementing cost-saving strategies, Dubai professionals can ensure efficient and effective project management while keeping budgets in check.