Understanding Designing Effective Negative Pressure Systems For Mold is essential. —

Discover the critical aspects of designing an effective negative pressure system for mold remediation. This article outlines key considerations for protecting indoor air quality while ensuring thorough and safe mold removal.

—

Understanding Designing Effective Negative Pressure Systems for Mold

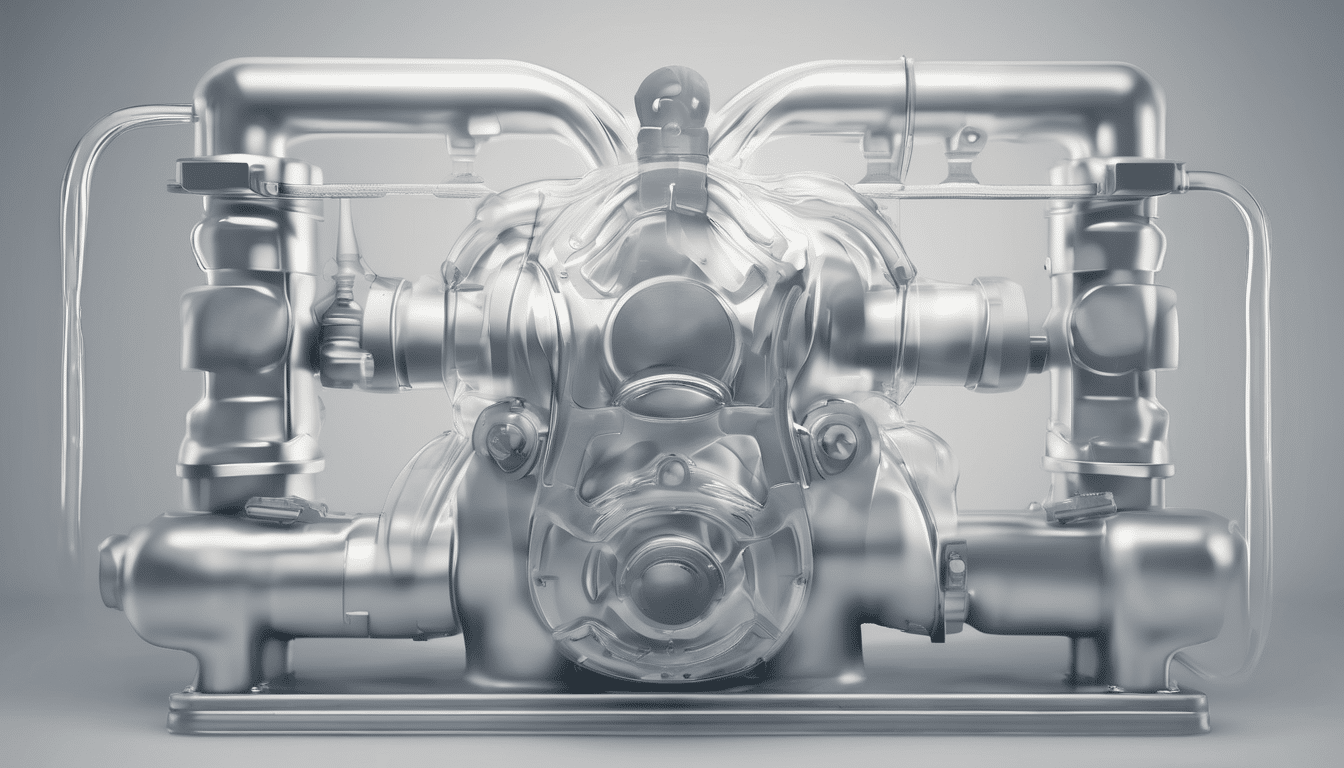

Designing effective negative pressure systems is crucial in preventing cross-contamination during mold remediation. These systems help maintain indoor air quality and ensure that contaminated air does not spread to unaffected areas of a building. This relates directly to Designing Effective Negative Pressure Systems For Mold.

Why Negative Pressure?

Negative pressure systems work by creating a suction effect, drawing contaminated air towards the containment area rather than allowing it to circulate freely. This is particularly important in enclosed spaces where mold spores and other contaminants can easily spread.

Designing Effective Negative Pressure Systems For Mold – The Importance of Negative Pressure Systems in Mold Remediat

Effective negative pressure systems play a vital role in ensuring the safety and efficiency of mold remediation projects. They help prevent the spread of mold spores, reduce the risk of cross-contamination, and maintain indoor air quality.

Controlling the Spread of Mold

By creating a controlled environment within the containment area, negative pressure systems ensure that any airborne mold spores are captured before they can spread to other parts of the building. This is especially critical in areas with sensitive occupants such as healthcare facilities or schools.

Negative vs Positive Pressure Systems: Key Differences and Considerations

Understanding the differences between negative and positive pressure systems is essential when designing an effective mold remediation strategy. Both have their advantages, but the choice depends on the specific project requirements. When considering Designing Effective Negative Pressure Systems For Mold, this becomes clear.

Negative Pressure Systems

- Containment Effectiveness: Negative pressure systems are excellent for containing contaminants and preventing cross-contamination.

- Air Quality Control: They help maintain indoor air quality by drawing contaminated air towards the containment area.

- Use in Containment Areas: Ideal for use within containment areas where mold removal is taking place.

Positive Pressure Systems

- Air Supply: Positive pressure systems provide a steady supply of clean air to unaffected areas, ensuring that the building’s overall air quality remains high.

- Prevention of Contamination Spread: They can be used in conjunction with negative pressure systems to prevent contaminants from escaping the containment area.

- Use in Unaffected Areas: Suitable for areas where mold remediation is not taking place but must maintain high air quality.

Designing Effective Negative Pressure Systems for Mold

Proper design of negative pressure systems is crucial to their effectiveness. Here are some key considerations:

Identifying the Containment Area

The first step in designing a negative pressure system is identifying the specific containment area where mold remediation will take place. This should include all affected areas, such as walls, floors, and ceilings.

Airflow Considerations

Ensure that airflow is properly managed to prevent contaminated air from escaping the containment area. Use appropriate sealing techniques and ensure there are no gaps or leaks in the system.

Equipment Selection

Select high-quality equipment such as HEPA filters, negative pressure fans, and ducting systems that can handle the volume of air required for the project. Ensure all components are compatible and provide optimal performance. The importance of Designing Effective Negative Pressure Systems For Mold is evident here.

Sealing and Containment Strategies for Preventing Cross-Contamination

Effective sealing and containment strategies are essential in preventing cross-contamination during mold remediation. Here are some best practices:

Critical Sealing Points

- Walls and Floors: Seal all gaps around walls, floors, and skirting boards to prevent air from escaping.

- Ceiling Plenums: Seal any ceiling plenums or ductwork to ensure that no contaminated air can circulate.

- HVAC Systems: Shut down HVAC systems during remediation to avoid circulating mold spores throughout the building.

Containment Techniques

- Bagging and Sealing: Use heavy-duty plastic bags or containment barriers to seal off affected areas. Ensure that these are properly sealed to prevent any leaks.

- HVAC Containment: If using negative pressure, ensure that the HVAC system is properly contained to avoid spreading contaminants through the building’s air distribution network.

HEPA Filtration in Negative Pressure Systems: Best Practices

High-efficiency particulate air (HEPA) filtration is a critical component of effective negative pressure systems. Here are some best practices:

Choosing the Right Filter

- Filter Efficiency: Select HEPA filters with a minimum efficiency rating of 99.97% for particles as small as 0.3 microns.

- Durability and Maintenance: Choose durable filters that require minimal maintenance to ensure continuous operation during the remediation process.

Filter Placement

- Primary Filter Location: Place primary HEPA filters as close to the containment area as possible to capture the largest amount of airborne contaminants.

- Secondary Filter Protection: Use secondary filters to protect primary ones from damage by larger particles or debris.

Professional Training and Certification for Effective Mold Remediation

To ensure the success of mold remediation projects, professional training and certification are essential. Here’s why:

Industry Standards

- Training Programs: Participate in industry-standard training programs that cover all aspects of mold remediation, including negative pressure system design.

- Certification Bodies: Obtain certifications from recognized bodies such as InterNACHI (International Association of Certified Home Inspectors) or IAC2 (International Association of Certified Indoor Air Consultants).

Continuing Education

- New Technologies: Stay updated on new technologies and best practices in mold remediation to ensure that your systems are always state-of-the-art.

- Regulatory Compliance: Ensure that you comply with local regulations and guidelines for mold remediation, including the design and implementation of negative pressure systems.

Conclusion

Designing effective negative pressure systems is crucial in preventing cross-contamination during mold remediation. By understanding the importance of these systems and following best practices, you can ensure that your projects are safe, efficient, and successful. Understanding Designing Effective Negative Pressure Systems For Mold helps with this aspect.

Verdict:

The choice between negative and positive pressure systems depends on the specific needs of each project. Negative pressure systems excel in containing contaminants and maintaining indoor air quality during mold remediation. Proper design, sealing, and containment strategies, along with HEPA filtration, are essential for effective implementation.

Expert Tips

- Engage Professional Consultants: Work with experienced consultants who can provide guidance on system design and implementation.

- Use High-Quality Equipment: Invest in high-quality HEPA filters, fans, and ducting systems to ensure optimal performance.

- Conduct Regular Inspections: Perform regular inspections of the negative pressure system to identify any potential issues early on.

FAQ

- Q: How often should I inspect my negative pressure system?

- A: Inspect your system at least once a week during active remediation and daily for the first few days after the process is complete.

- Q: Can I reuse HEPA filters from one project to another?

- A: It’s not recommended. Filters should be replaced or thoroughly cleaned before reuse, as they can become contaminated during use.

- Q: How do I maintain positive pressure systems in unaffected areas?

- A: Ensure that HVAC systems are functioning correctly and that doors and windows are sealed to prevent air leakage. Use HEPA filters if necessary.

Designing Effective Negative Pressure Systems For Mold factors into this consideration.

Call to Action

For more information on designing effective negative pressure systems, contact our team at Saniservice for professional guidance and support in Dubai, UAE.

—

designing effective negative pressure systems, mold remediation, cross-contamination prevention, HEPA filtration, containment strategies